In the fast-paced world of pharmaceuticals, the importance of raw materials has never been more vital. These substances form the backbone of every medication and treatment we produce, underpinning the safety and efficacy of drugs that millions rely on every day. As manufacturers, we take immense pride in our rigorous approach to selecting and testing these critical components. Our journey towards ensuring impeccable quality in healthcare begins right at the sourcing of these materials.

Understanding pharmaceutical raw materials is not just about knowing their names or chemical properties. It involves a deep dive into their origins, how they interact with other substances, and their impact on the human body. Ensuring that these materials are of the highest quality is our top priority, as this directly influences the effectiveness and safety of the final pharmaceutical products.

Given our commitment to global health standards, we have established stringent protocols for sourcing and approval. Each material is subjected to rigorous testing to confirm its purity and suitability. In this context, let’s explore the nature of pharmaceutical raw materials, the different types employed, and the critical role they play in the medicine manufacturing process.

What Are Pharmaceutical Raw Materials?

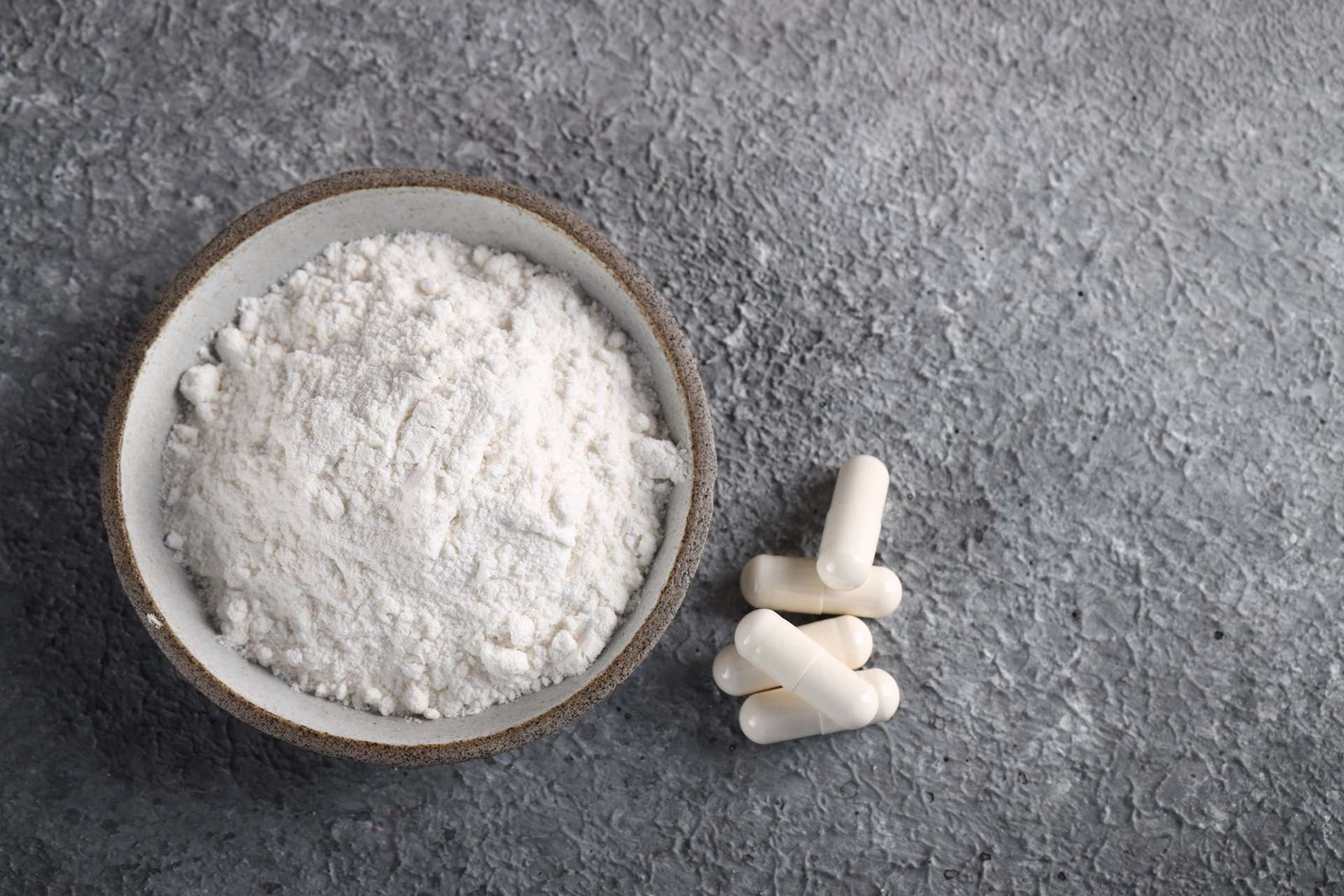

Pharmaceutical raw materials include all substances that are used in the production of medicinal products. They serve as the foundation from which everything from basic over-the-counter painkillers to sophisticated biologic treatments is created. These materials can broadly be classified into two main categories: active pharmaceutical ingredients (APIs) and excipients. APIs are the primary components that produce the intended effects of the medication. Excipients, on the other hand, are substances that help convey or deliver the medication into the system, serving roles such as fillers, binders, preservatives, and stabilisers.

Both types of materials must meet stringent regulatory standards to guarantee patient safety and drug efficacy. We ensure every substance is examined to comply with established medical standards before it is used in the manufacturing process. Understanding what pharmaceutical raw materials are and their critical roles can significantly impact the development and quality of the final pharmaceutical products that we help create.

Types of Raw Materials Used in Medicine Manufacturing

The variety of raw materials used in pharmaceutical manufacturing is vast, yet they can strategically be categorised into key types, each serving unique purposes. Here are the primary categories:

1. Active Pharmaceutical Ingredients (APIs): These are the core functional components of any drug, responsible for the therapeutic effects.

2. Excipients: These are non-active components but are crucial for delivering the medication into the system effectively. Excipients include:

– Solvents: Used to dissolve other substances.

– Binders: Provide adhesion to the tablet compounds.

– Coatings: Enhance tablet shelf life and mask taste.

– Fillers: Add volume to tablets making them easier to handle.

3. Intermediates: These are the substances produced during the steps of the synthesis of APIs. They can sometimes themselves be marketed as APIs.

4. Raw Chemical Materials: These include basic chemicals used in synthesis, such as reagents, catalysts, and solvents.

Understanding these materials and their roles allows manufacturers like us to tailor production processes that enhance the efficacy, safety, and stability of pharmaceutical products. Employing high-quality materials in appropriate combinations underpins our commitment to healthcare and our role in advancing medicine.

Our Process for Sourcing and Testing Raw Materials

At our core, the rigorous process we use to source and test raw materials sets us apart in the pharmaceutical industry. Ensuring the purity and potency of the materials that go into medicines is critical for their effectiveness and safety. We start by selecting only the highest quality suppliers who meet our stringent standards for quality control and ethical practices. We closely monitor each step of the supply chain to maintain the integrity and quality of raw materials received.

Once materials arrive at our facilities, they undergo a series of meticulous testing procedures. This includes identity testing, to ensure the material matches its specification; purity testing, to detect any impurities; and potency testing, to confirm its effectiveness. We also conduct stability tests to understand how substances behave under various conditions over time. All these measures help ensure that only the best-quality materials are used in the manufacture of drugs, ensuring safety and efficacy for users.

The Importance of High-Quality Raw Materials in Pharmaceuticals

The quality of pharmaceutical raw materials is paramount because it directly impacts the safety and effectiveness of the finished product. High-quality materials help ensure that medications perform as expected, offering the therapeutic benefits that are needed without undue risk of harm or adverse effects. This commitment to quality not only helps improve patient outcomes but also reinforces public trust in healthcare providers and drug manufacturers.

Furthermore, utilising premium raw materials reduces production issues that can cause delays and increase costs. It minimises the risk of product recalls, regulatory fines, or litigation, all of which can be detrimental to a company’s reputation and financial stability. Maintaining stringent quality control throughout the sourcing and manufacturing processes underscores our commitment to safety and our dedication to contributing positively to the public health sector.

Conclusion

The journey of manufacturing safe and effective pharmaceuticals begins with the careful selection and handling of raw materials. Throughout our exploration of what pharmaceutical raw materials are, their types, and the rigorous process we employ in their sourcing and testing, it is clear that each step is critical to our mission. We at Venus Marketing remain committed to upholding the highest standards of quality and integrity in all our pharmaceutical products.

This commitment is a cornerstone of our brand promise, ensuring that we meet the needs of healthcare providers and patients who rely on us for reliable, safe, and effective medications. For more information about our processes or to learn more about how we can serve your API pharmaceutical needs, contact Venus Marketing today. We are here to be your trusted partner in healthcare.